News

SME success stories within the Vanguard Initiative – an interview with a representative from Bond High Performance 3D Technology

SME success stories within the Vanguard Initiative – an interview with a representative from Bond High Performance 3D Technology

In these unprecedented times, SMEs across Europe are facing profound transformation processes in which the technological challenges are becoming ever greater and, at the same time, the need of embracing the twin (digital and green) transition needs to be tackled quickly and decisively. Therefore, a strong positioning on the national and international market is a crucial success factor for small and medium-sized enterprises. External support through cooperations can be an important factor, but these are rarely free or without strings attached.

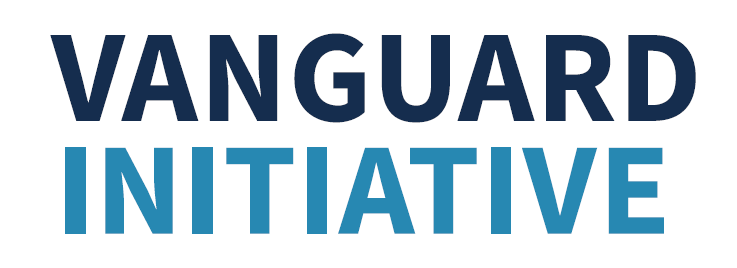

The Vanguard Initiative and its initiated SME Success Stories support program precisely tackles these challenges. Three Enterprises (AddCat B.V., Remembrane Srl. and Bond High-Performance 3D Technology) have been selected and supported by building cross-regional innovation practices. The program aimed to promote the participation of these companies in the activities of the Vanguard Initiative in order to foster interregional value chains and accelerate market adoption of their products and services.

The selected companies not only benefited from the strong network and experience of the Vanguard Initiative experts, but were also able to stimulate and expand interregional partnerships and collaborations in the Vanguard regions through an innovation voucher.

We met with a representative of one of the selected companies, Bond High Performance 3D Technology, to discuss their experiences of the SME Success Stories Program and the story behind their enterprise.

Hi, I’d like to start this interview by asking you about the collaboration that you put in place with the university of Oulu in Finland – you started this partnership thanks to the SME success stories program is that right?

Yes – It was actually The East Netherlands Development Agency OostNL who suggested Bond 3D to participate to the program and also made the suggestion for a partner: The University of Oulu Finland. That turned out a valuable suggestion. Indeed, the cooperation was valuable for Bond3D and prior to this cooperation, this partner was not on our radar.

The program enabled us to extend our network: The role of the team from the university of Oulu in the project was to do a series of tests to enable Bond3D to obtain further insight into long term properties (fatigue, creep) of our polymers after printing. Furthermore, Bond3D has obtained insight into the material properties of our printed products at elevated temperatures.

I understand that Bond 3D is innovating in the field of 3D printing, could you tell us a bit more about Bond3D and about your innovations in the field of 3D printing?

Our SME, Bond3D, was founded in December 2014 as a limited liability company and is based in Enschede (Netherlands). Today, we have a team of 70 professionals in competencies spanning technology development; sales and marketing; application development; production; and supply chain. Our technology is unique in addressing the challenges of printing functional parts from high-performance polymers: at Bond3D a unique patented high performance polymer printing technology (The Bond3D technology) is developed to print high performance polymers, uniformly strong and voidless. The Bond3D technology is capable of printing parts with a strength comparable to the strength of moulded or machined parts. Our programs are focused to adapt the printing process to the material instead of manipulating the material to make it printable. As a result, the inherent material characteristics are maintained by using The Bond3D technology.

Our SME, Bond3D, was founded in December 2014 as a limited liability company and is based in Enschede (Netherlands). Today, we have a team of 70 professionals in competencies spanning technology development; sales and marketing; application development; production; and supply chain. Our technology is unique in addressing the challenges of printing functional parts from high-performance polymers: at Bond3D a unique patented high performance polymer printing technology (The Bond3D technology) is developed to print high performance polymers, uniformly strong and voidless. The Bond3D technology is capable of printing parts with a strength comparable to the strength of moulded or machined parts. Our programs are focused to adapt the printing process to the material instead of manipulating the material to make it printable. As a result, the inherent material characteristics are maintained by using The Bond3D technology.

At Bond3D, material research is being performed to develop the process to create the best printed parts possible. The material research currently focusses mainly on short-term material properties (e.g. tensile or compressive strength) and includes microscopic research of the printed structures using optical microscopes. For more advanced research, partners are used and the Innovation Voucher from SME success stories gave us the opportunity to enrich test data with support from the University of Oulu.

Your partnership with the university of Oulu seems to have been fruitful, what would you say is the added value of the program and would you recommend other SMEs to participate in it?

Since Bond3D did not cooperate earlier with the university of Oulu there was an element of uncertainty on the value of the outcomes but the cooperation turned out to be very valuable and the results from the work done by the university were very useful. Throughout the entire process the SME Success Stories Team was very supportive and their communication was very clear on the process and the deliverables. Based on this experience, we endorse and recommend other SME companies to participate in the programme and explore new paths in their development.